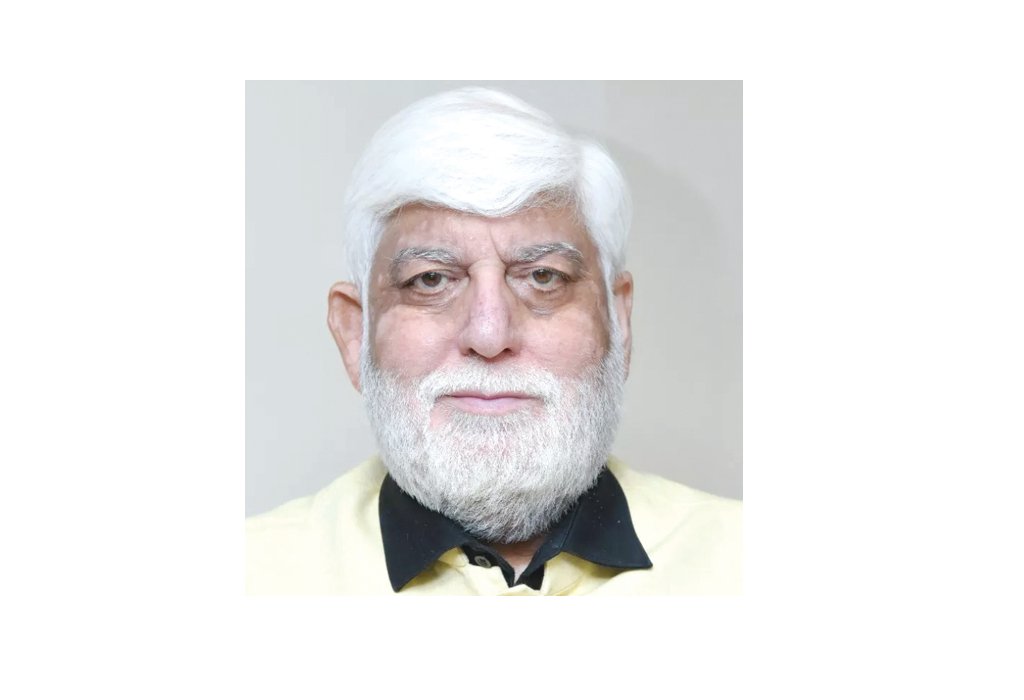

Vipin Vohra, highlights how automation and robotics are enhancing efficiency in the fashion supply chain. He also discusses sustainability challenges, last-mile delivery improvements, supply chain resilience, regulatory impacts, and benefits from infrastructure and digital initiatives.

Automation, sustainability, and resilience drive the evolution of fashion logistics

Vipin Vohra, Chairman of Continental Carriers, explains the transformative impact of automation and robotics in the fashion supply chain. These technologies are driving efficiency, accuracy, and speed, with automated warehouses and robotic systems revolutionising inventory management and order fulfillment. While integration comes with challenges like high initial costs and complexity, the benefits are clear: increased productivity, improved supply chain visibility, and better adaptability to market trends. Vohra’s insights show how these advancements are not only reshaping production but also boosting competitiveness and customer satisfaction in the fashion industry.

Sustainability challenges

The fashion industry faces significant sustainability challenges in logistics and supply chain management, including high carbon emissions, waste from overproduction, and poor labour practices. Additionally, dependence on non-renewable resources and inefficient reverse logistics worsen environmental impacts. Addressing these issues requires adopting sustainable practices such as optimising transportation routes, using eco-friendly materials, and enhancing transparency. These efforts are key to building a more ethical and environmentally responsible fashion industry.

Delivery excellence

Last-mile delivery plays a crucial role in the fashion customer experience, directly influencing satisfaction and brand loyalty. Meeting the high expectations of the fast-paced fashion market requires efficient and timely deliveries. Companies should invest in advanced technologies like real-time tracking and route optimisation while collaborating with local couriers for better speed and reliability. Offering flexible delivery options, such as same-day or next-day service and easy returns, can significantly improve the shopping experience, boost customer retention, and strengthen brand perception.

Resilient supply

To build resilient supply chains, the fashion industry must diversify suppliers and sourcing regions, reducing dependency on single areas. Embracing technologies like AI and blockchain enhances transparency and risk management. Investing in local production and flexible manufacturing helps mitigate disruptions, while strong supplier relationships and strategic stock reserves ensure continuity during crises. By monitoring geopolitical developments and adapting proactively, the industry can manage risks more effectively, creating a robust and adaptable supply chain.

Regulatory shifts

Evolving government regulations are reshaping fashion logistics. Sustainability mandates push for eco-friendly packaging and route optimisation to reduce carbon footprints. Stricter labour practices promote fair wages and better working conditions, while data privacy laws require strong cybersecurity measures to protect customer information. These regulations are driving the industry towards greater responsibility, leading to investments in compliance, technology, and sustainable practices. Additionally, the Union Budget 2024’s focus on infrastructure and digital initiatives will significantly benefit the fashion sector. Upgraded logistics networks will streamline supply chains, reduce costs, and speed up delivery. Digital support for e-commerce will expand brand reach, while smart manufacturing investments will spur innovation, boosting global competitiveness and fostering a more dynamic and resilient fashion ecosystem.