PepsiCo Polska partners with Mecalux to launch a 24/7 smart warehouse, boosting capacity, cutting costs, and reducing CO₂ emissions.

PepsiCo Polska is gearing up for a major leap in logistics automation with the launch of a next-generation smart warehouse powered by Mecalux technology. Expected to go live in the third quarter of 2026, the new automated storage and retrieval system (AS/RS) in Grodzisk Mazowiecki, Poland, will seamlessly connect production to dispatch, operating 24/7 to enhance efficiency and sustainability.

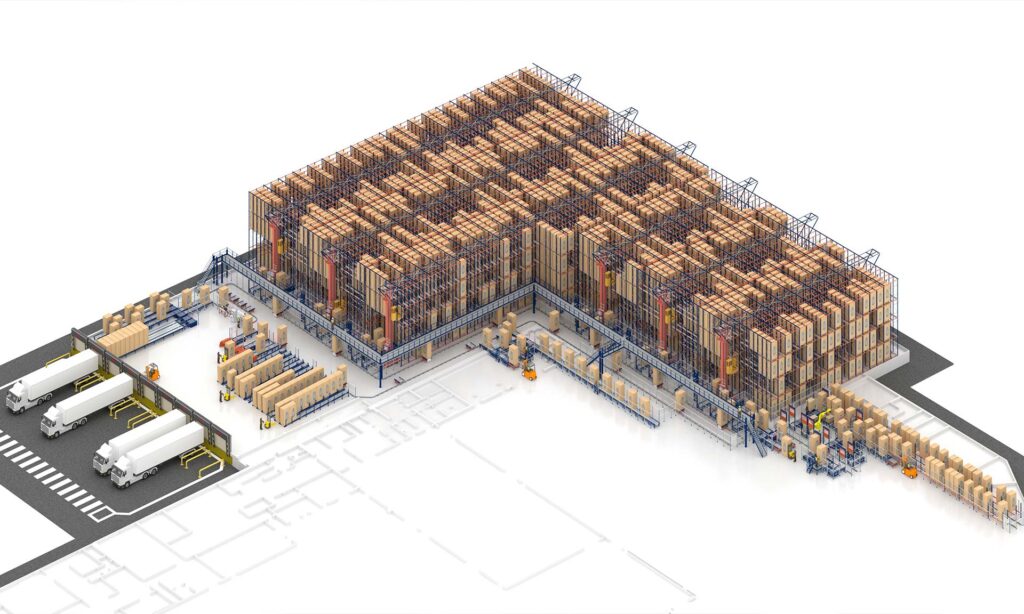

Designed to store potato crisps and a variety of PepsiCo snack products, the fully automated solution boosts capacity without expanding the existing facility. The project includes six stacker cranes with automated pallet shuttle-equipped racking, an electric monorail system, and automatic conveyors ensuring uninterrupted pallet movement directly from production lines.

The smart warehouse will be managed via Mecalux’s Easy WMS, integrated with PepsiCo’s SAP eWM, enabling real-time coordination from inbound to outbound logistics.

“Our modular automation design connects production, warehousing, and dispatch end-to-end,” says Bartłomiej Lesiuk, Warehouse Automation Design Manager, PepsiCo. “This gives us flexibility to scale operations as needs evolve.”

This marks Mecalux’s third warehouse project for PepsiCo Polska. The system features energy-saving stacker cranes, cutting consumption by 15–20%, and AI-driven computer vision for precise pallet handling. PepsiCo also expects to cut 200 tonnes of greenhouse gas emissions annually, reduce logistics costs, and eliminate double handling with direct deliveries.

Source: PR