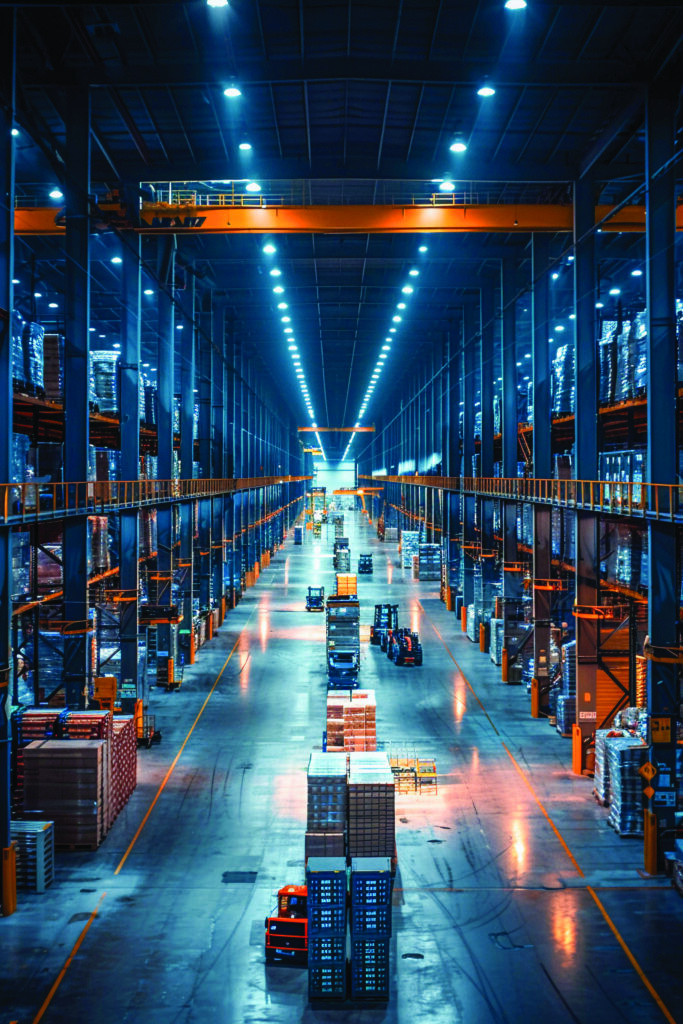

To meet growing demands of speed, scale, and sustainability, warehousing is undergoing a smart transformation. This feature captures expert insights on flexible design, bonded facilities, automation, flooring, and material handling. Stakeholders across the value chain share practical solutions shaping India’s next-generation warehousing ecosystem.

“Airport-based bonded warehouses improve international cargo movement by deferring duty payments, enabling on-site inspections, and reducing clearance delays. They also serve as inventory buffers, helping businesses consolidate shipments, manage stock efficiently, and better align with market demand—delivering not just speed, but smarter supply chain control.”

“Industrial parks support multimodal transport by being located near highways, rail terminals, ports, and airports. This strategic positioning ensures smooth transfers between transport modes, cutting transit times and costs. On-site facilities like freight stations and warehouses further boost operational efficiency.”

“For medium-sized warehouses, simple automation tools like barcode scanners, RFID systems, and automated conveyors can significantly boost efficiency. These improve accuracy and reduce manual effort. A Warehouse Management System (WMS) adds further value by optimizing space, guiding picking processes, and offering real-time inventory insights—all with minimal disruption and quick ROI.”

“Bonded warehouses at Air Freight Stations (AFS) play a vital role in speeding up international cargo movement. They allow cargo to be received, consolidated, customs-cleared, and dispatched just in time for flights, reducing airport terminal congestion. Exporters can complete documentation and compliance right at the AFS. Dedicated customs officials onsite speed up inspections and clearances, cutting down delays common at busy airports. Managing cargo closer to manufacturing hubs in a controlled environment reduces mishandling risks, protecting cargo integrity and boosting customer trust. Overall, AFS bonded warehouses enable smoother logistics, faster processing, and quicker exports.”

“For time-sensitive and high-value goods like pharmaceuticals, electronics, and perishables, AFS bonded warehouses offer secure, temperature-controlled handling with real-time monitoring. Our RA-3 certified facility ensures compliant, secure handling for regulated markets like the UK and EU. With 24/7 operations and strict standards, it supports urgent shipments and just-in-time deliveries reliably.”

“To ensure smooth customs, we employ BCAS-certified security and screen all cargo with BCAS-approved X-ray machines. The facility has 24/7 CCTV surveillance and integrates with ICEGATE, working closely with customs for transparent and timely clearance.”

“The biggest advantage of having a bonded warehouse within or near a seaport CFS is cost saving and convenience. Since direct clearance from the port for bonded cargo isn’t available, having the bonded facility within the CFS area creates a one-stop solution. It reduces transportation needs and simplifies the logistics process.”

“Importers often use bonded warehouses for cargo like perishables or pharmaceuticals, which require multiple clearances. Being at the port ensures that relevant authorities—such as FSSAI, ADC, or other regulatory bodies—are close by, enabling faster sampling, quicker reports, and faster cargo clearance.”

“Bonded warehouses at the port also support value-added services like relabelling, repackaging, and processing—all under one roof. This streamlines operations and improves turnaround time.”

“Compliance remains the same whether the warehouse is at the port or elsewhere. Since bonded cargo is under customs control, all regulations and SOPs must be strictly followed.”

Designing future-ready warehouses starts with assessing the location and the warehouse’s role in the supply chain. This helps define a clear plan covering infrastructure, building specifications, and support systems. Today’s warehouses are more than storage spaces—they are processing centres that require scalable operations, flexible layouts, and integration of automation and digital systems. A strong floor, smooth equipment movement, multi-vehicle access, and energy-efficient features aligned with green building standards are essential.

Location plays a vital role in improving delivery speed and reducing transportation costs. It must offer good road connectivity, planned infrastructure, reliable utilities, and a supportive operational ecosystem.

Balancing sustainability with cost and timelines requires smart choices—like using locally sourced, eco-friendly materials, minimizing waste, and incorporating natural light, ventilation, and prefabricated structures. These choices reduce environmental impact, save on costs, and improve construction speed, all while supporting long-term efficiency and employee well-being.

“Modern industrial parks are evolving with a strong focus on Grade A, scalable spaces built to global standards. At Horizon, we prioritize ready-to-move inventory and fast build timelines, with custom-built solutions now accounting for 50% of our deliveries, especially for manufacturing and automotive sectors. Compliance with environmental, fire safety, labor, and statutory norms is now standard, ensuring smooth, audit-ready operations. Sustainability and smart tech are rising priorities, and we aim to have all parks green-certified by year-end.”

“Tenants today demand efficient traffic circulation, infrastructure supporting heavy automation and material handling equipment, 24/7 security, and robust utility backups. Technology-driven park management—like smart monitoring, visitor management, and uninterrupted connectivity even in remote areas—is essential.”

“Industrial parks support multimodal transport through strategic site selection near expressways, ports, airports, and rail hubs. We collaborate with local authorities to enhance access roads, integrating first and last-mile infrastructure into master plans to benefit customers and the region alike.”

“Gender diversity in warehousing is vital—not just culturally, as echoed in the verse ‘Yatra Pujyate Nariyasu, Tatra Ramante Devta’, but also strategically. Diverse teams reduce attrition, improve problem-solving, and drive innovation. Welcoming women into logistics roles—from operations to leadership—makes the industry more efficient, resilient, and future-ready.”

“To foster inclusivity, warehousing must break outdated norms through focused action. This includes showcasing women’s success stories, offering AI-enabled training and mentorship, and implementing inclusive HR policies like flexible schedules and secure workspaces. Industry perceptions should shift through inclusive branding and male allyship. Women should be encouraged into non-traditional roles—like forklift operators or supply chain leaders—through targeted career paths. Finally, partnerships with initiatives like WiLAT and government skill programs can scale up diversity. Together, these steps create a more equitable and dynamic logistics ecosystem.”

“Indian warehouses are evolving rapidly with trends like higher dock requirements, ample trailer parking, and optimized vehicle movement to maximize space and throughput. Big box formats are in demand, especially for e-commerce and 3PLs. Flexible layouts supporting cold storage to last-mile fulfilment are becoming standard, helping reduce costs and boost responsiveness in fast-paced logistics.”

“Location strategy is crucial for controlling costs and improving efficiency. Warehouses near industrial hubs or transport corridors cut delivery times and expenses. Multimodal access—close to freight corridors and expressways—adds resilience and enhances customer service, making it a key factor in competitive warehousing.”

“Customers want automation-ready, ESG-compliant warehouses. Designs now include wide column grids, efficient layouts, and green infrastructure to support robotics and automation. ESG goes beyond solar panels to include worker safety and ethical labor, attracting conscious customers and investors while ensuring compliance and long-term efficiency.”

“For modern warehouses with heavy equipment and high movement, flooring must offer high abrasion resistance, load-bearing capacity, dust-free surfaces, and low maintenance. Using high-grade concrete with proper reinforcement and surface hardeners is key. Ensuring strict flatness and levelness tolerances enables faster forklift movement and higher throughput. Minimizing joints and using armored ones prevents damage. Sub-base stability must be achieved through proper compaction and verified by independent testing agencies for quality compliance.

Regarding safety and maintenance, good flooring prevents slips, skids, and equipment toppling. A flat, level surface ensures safe MHE operations. Densified, dust-free floors improve air quality and protect finished goods from dust. Quality flooring resists cracks and surface wear, reducing repairs, MHE maintenance, and downtime, thus enhancing efficiency.

In automated and climate-controlled warehouses, superflat floors like TR34 DM1 or ASTM Fmins enable precise AGV and robot movement. Jointless designs, insulation systems, vapor barriers, and epoxy or PU coatings improve hygiene, safety, and durability.”