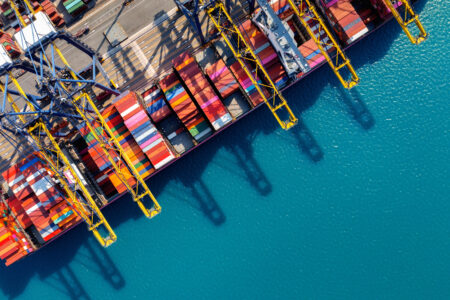

A study of 107 vessels shows AI-driven watchkeeping sharply reduces near misses and boosts maritime safety.

Maritime safety has received a major boost thanks to artificial intelligence. A study by Orca AI has revealed that its virtual watchkeeping technology has cut high-severity close-quarter incidents at sea by an impressive 58 percent.

The research involved 107 container ships equipped with Orca AI’s Seapod system, collectively sailing the equivalent of 116 ship-years and covering over 8 million nautical miles. By comparing the first three months of deployment with the last three months of the year, Orca AI was able to measure the system’s real-world impact. In the early phase, vessels averaged 3.3 high-severity events per month, which dropped to 1.4 events per month after sustained use of the AI system.

Speaking at a seminar in Singapore, jointly organised with P&I Club NorthStandard, Orca AI CEO and co-founder Yarden Gross said that increasingly congested waterways, like the English Channel, Malacca Straits, and major Chinese ports, combined with global crew shortages, make watchkeeping a critical yet challenging task. “Those are the challenges AI is built to solve,” Gross noted, emphasising that automating tedious but essential duties allows crews to focus on higher-level decision-making.

The technology is already gaining traction among top global shipping players. Maran Tankers Management and Eastern Pacific Shipping are among the early adopters. Captain Giorgos Asteros, Operations Director at Maran Tankers, said Orca AI data has helped the company refine vessel instructions at Ningbo Port, including optimal speed and berthing schedules. The result: less pressure on crews and safer operations for ships and ports alike.

With shipping lanes worldwide becoming busier, Orca AI’s virtual watchkeeping technology demonstrates the real potential of AI in enhancing maritime safety, reducing human error, and protecting lives and cargo. As more vessels adopt such systems, the future of shipping could see safer seas and smarter operations, powered by intelligent automation.

Source: SMN