Agricultural exports are a vital component of global trade, contributing to food security and economic growth. However, the logistics sector plays a pivotal role in ensuring the seamless movement of goods across borders, particularly for sensitive categories like bulk commodities, perishable produce, and fisheries. Each category presents unique challenges, from the large-scale handling of grains and pulses to maintaining the freshness of time-sensitive perishables and seafood. Efficient logistics solutions are crucial to overcoming these hurdles, ensuring that agricultural exports not only meet international demand but also adhere to quality standards. This discussion delves into the key logistical considerations for each segment and explores strategies to optimise the supply chain for agricultural exports.

The most essential factor in seafood exports is the cold chain, which must remain intact throughout the transport process. It is not only important to maintain the correct temperature but also to ensure zero fluctuations during transit. Temperature variations can cause the protective water glaze on seafood products to melt, which directly impacts their quality and shelf life.

Cold storage facilities at ports and airports should be available, enabling customs inspections under controlled environments. When seafood is removed from reefer trucks for inspection, temperature shocks must be avoided by ensuring the vehicles open directly into temperature-controlled areas at ICDs, CFSs, or port facilities.

Monitoring Reefer Points and Temperature Integrity: While waiting for loading onto vessels or aircraft, functional reefer points are crucial to maintain the cargo’s temperature. Often, the importance of monitoring reefer points is underestimated, leading to unexpected temperature variations that degrade product quality.

We must ensure that reefer points at ports and airports are properly maintained and monitored. The use backup power systems and keep a trained mechanic on standby to address any equipment malfunctions or power failures.

Continuous Temperature Monitoring: Throughout the journey, temperature monitoring devices like data loggers should be employed to detect any mishandling or fluctuations. These devices provide real-time data that ensures accountability across the supply chain and helps identify problems before they escalate.

Seamless Connectivity for Air and Sea Transport: Finally, ensuring consistent air and vessel connectivity is essential to avoid disruptions when the cargo is brought to the airport or port for shipment. Proper planning and coordination with shipping lines or airlines prevent unexpected delays, ensuring that the seafood reaches international buyers on time and in optimal condition.

Therefore, to successfully export seafood like prawns, exporters must focus on maintaining a strict cold chain, functional reefer points, continuous temperature monitoring, and smooth transport connectivity. Investments in infrastructure and meticulous planning can prevent temperature shocks and delays, ensuring that products reach buyers fresh and compliant with international quality standards.

Boosting agri-exports and supply chain resilience

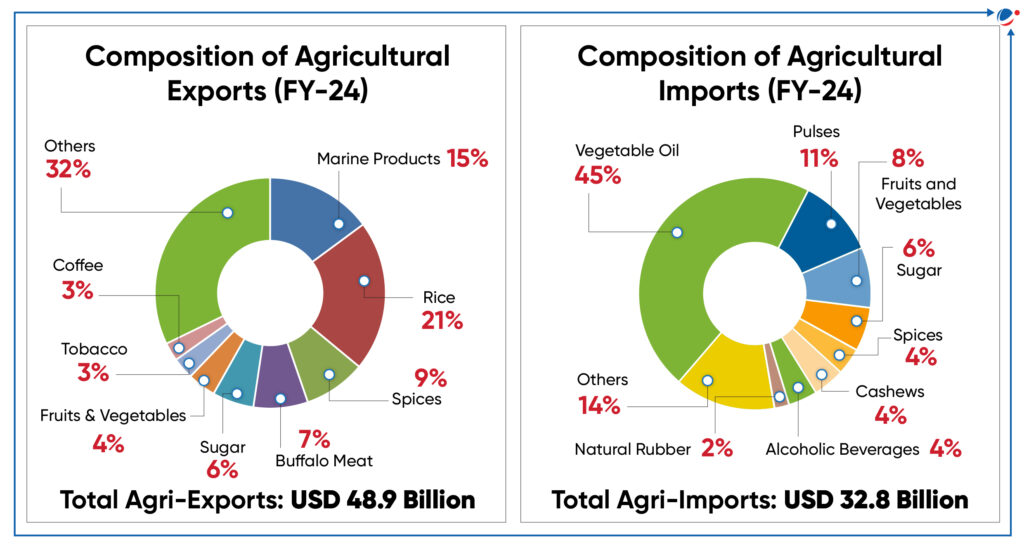

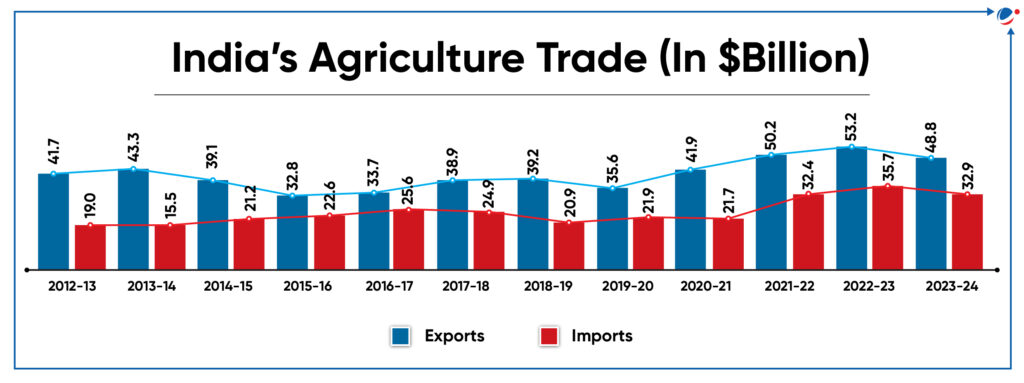

With an 11 percent share in India’s USD 437 billion exports, agriculture is indeed a vital sector. Reducing waste and enhancing the supply chain for perishables require prioritising cold chain logistics, temperature-controlled warehouses, reefer vans, and containers, along with regular training in handling and packaging. Significant initiatives, including the Agri Export Policy, OPOP, and PMKSY, aim to build a supportive ecosystem. States are also developing action plans, contributing to an impressive 32% growth in fresh fruit exports, reaching over USD 1 billion in 2023-24. These collaborative efforts are expected to streamline the supply chain and boost exports.

To bolster resilience against price fluctuations, Indian businesses should diversify their supplier and buyer bases and adopt sustainable, ethical sourcing practices. Securing necessary certifications and leveraging new technologies can also enhance supply chain adaptability amid global uncertainties.

Rising fuel and metal costs notably impact logistics expenses, which affects export competitiveness, especially in low-margin sectors. Companies can mitigate these costs by fostering long-term partnerships with logistics providers for more favourable rates during price shifts. Optimising shipment consolidation, improving load efficiency, and minimising loading/unloading during transit are additional strategies to keep transportation costs under control.

Tackling India’s post-harvest losses

India’s agricultural losses and damages exceed global standards, primarily due to inefficiencies in post-harvest handling. Losses are substantial, especially in perishable commodities like fruits and vegetables, with 15–25% of agricultural produce lost annually. For some perishable items, losses can reach as high as 30-40%. These losses are attributed to multiple factors, including inadequate storage facilities, fragmented and insufficient cold chain infrastructure, high transportation costs coupled with prolonged transit times, and low rates of technology adoption. Additionally, issues with quality control, seasonal variations, and complex government regulations compound the challenges. Inconsistent packing standards, limited market access, and a shortage of skilled labour in modern handling techniques further exacerbate the situation.

The interconnected nature of these issues demands collaborative efforts from all stakeholders, including both central and state governments, cooperative societies, the private sector, commodity trade associations, service providers, and academics.

Best practices implemented in certain regions of India should be studied and expanded to broader areas. Furthermore, as most loss values are approximations, a robust method is needed to measure these losses and their causes, enabling prioritisation and a comprehensive action plan.

Freshness Solutions for Perishable Exports

The logistics industry’s approach to preserving perishable exports is essential for the timely and efficient delivery of items like fruits and vegetables while minimising spoilage. This ongoing challenge has led to numerous innovations within the sector.

Supply chain experts have significantly advanced technologies and processes for transporting perishables. The development of controlled atmosphere (CA) storage systems, which regulate oxygen, carbon dioxide, and nitrogen levels in containers, has notably extended the shelf life of many products. Additionally, advanced tracking, monitoring systems, and AI technology enable logistics providers to predict and assess cargo conditions during transport, allowing for timely interventions when issues arise.

These initiatives have expanded consumer access to a broader variety of fresh produce, benefiting both consumers and creating new economic opportunities for farmers and exporters. However, challenges persist, including increasing demand for fresh produce and the need to reduce environmental impacts, prompting the exploration of sustainable biofuels and optimised transportation routes.

Looking ahead, the industry will likely continue to prioritise technological advancements, such as efficient refrigeration systems, AI-driven route optimisation, and alternative transportation methods like high-speed rail and drone delivery.

Preserving Freshness in Perishable Exports

P C Maity, Chairman, Airport Sub Committee, Air Cargo Complex, NSCBI Airport Kolkata

The logistics industry employs several strategies to preserve the freshness and quality of perishable exports, such as fruits, vegetables, and seafood. Minimising airline transit times is essential, as extended transport increases spoilage risks.

To address this, direct flights or optimised routes are prioritised, ensuring swift cargo arrival at destinations. Ground handling agents, like those appointed by AAICLAS, play a crucial role in maintaining product quality. Proper training in handling techniques helps reduce physical damage and spoilage during loading, unloading, and storage at airports, minimising temperature fluctuations and delays to maintain freshness.

Another key solution is the proximity of government-approved packhouses to air cargo terminals. Reducing the distance between packhouses and air cargo buildings enables quicker processing of cargo during phytosanitary (PQ) inspections and packaging. Additionally, inspection agencies such as FSSAI, PQ, AQCS, and MPEDA, which oversee the export of fresh fruits, vegetables, seafood, and other agricultural products, need offices either within or near the air cargo complex to expedite inspection and certification processes. This proximity reduces transit times and ensures optimal temperature and humidity levels, which are critical for perishable items like seafood.

Ensuring Freshness in Seafood Exports

Prithwish Biswas, Director, BISWAS AND ASSOCIATES

To safely and efficiently export fisheries and seafood, trailers used for transport must be in optimal condition, with up-to-date documentation for regulatory compliance and smooth transit. Skilled drivers experienced in handling time-sensitive perishable goods are essential for timely delivery, avoiding unnecessary delays. For long-distance transport, trailers equipped with Genset units maintain the cold chain, with technicians on hand to monitor temperatures and address any issues, ensuring uninterrupted refrigeration.

Marine products like prawns require controlled temperatures between -18°C and -25°C. Before departure, reefer containers must be pre-cooled to the desired temperature to preserve product quality. Throughout transit, technicians continuously monitor and adjust temperatures to prevent spoilage. Upon reaching the port or Container Freight Station (CFS), drivers promptly plug the reefer container into a power source. Documenting the temperature with photographic evidence adds accountability and safeguards product quality. These procedures are crucial for maintaining the freshness and safety of seafood, aligning with international standards, and ensuring customer satisfaction.